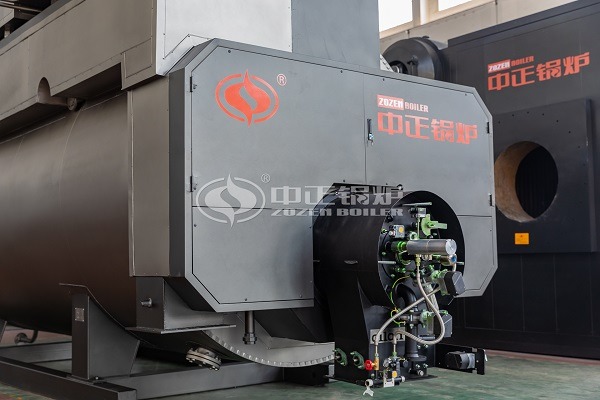

Steam boiler at low price in Wuxi Zozen Boilers Co.,Ltd. are high quality steam boiler used in petrochemical industry, food industry, manufacturing industry etc. Commonly used steam boilers are oil fired steam boilers, gas fired steam boilers, condensing gas/oil fired steam boilers, coal fired steam boiler, biomass fired boilers and so on. If you want the best steam boiler sales, please don’t hesitate to get the quote from Wuxi Zozen Boilers Co.,Ltd.! Zozen will provide you the best steam boilers with the low price!

Steam boiler refers to the boiler equipment that produces steam and belongs to special equipment. Its design, production, delivery, installation must be subject to the supervision of the technical supervision department, the user needs to obtain the boiler use certificate to operate the boiler. Different from atmospheric boiler, steam boiler must be with boiler procedures when leaving the factory, boiler procedures include boiler body diagram, installation diagram, instrument valve diagram, pipeline diagram and inspection certificate.

Steam Boiler Classification

- Steam boiler sales can be divided into electric steam boiler, oil-fired steam boiler, gas-fired steam boiler and so on according to the fuel;

- Steam boilers can be divided into manual combustion steam boilers and automatic chain combustion steam boilers according to the mode of fuel supply;

- According to the structure can be divided into vertical steam boilers, horizontal steam boilers, small steam boilers for single, double return vertical structure, large steam boilers for three return horizontal structure.

The steam boiler is a boiler shell type full wet backflow three return firework pipe structure. The flame is burned in a large combustion chamber with micro positive pressure, full extension, low burning heat load, high burning heat efficiency, effectively reducing smoke exhaust temperature, saving energy and reducing consumption, and making it economical to use. The structure of corrugated furnace tube and threaded pipe increases the heat absorption intensity of the boiler and satisfies the need of heat expansion of the heat exchange surface, which is scientific, reasonable and durable.

Steam Boiler Characteristics

- Fuel combustion is sufficient, boiler operation is stable and takes up less space, at the same time, there is a spoiler inserted in the smoke pipe to slow down the smoke exhaust speed, increase heat exchange, boiler thermal efficiency is high, reduce user cost;

- It reduces the exhaust temperature, saves energy and reduces consumption, and makes it more economical to use.

- Stable performance and complete functions;

- The whole machine has high automation degree and perfect safety protection. The operation process is fully automated;

- It adopts original imported burner, automatic programmed control, fan automatic purging and electronic automatic ignition.

- Using glass wool as through-body insulation, light weight, good insulation effect, less heat loss;

- Advanced steam boiler special computer controller, beautiful appearance, rich display;

- With boiler water level intelligent control, steam pressure control, limit low water level alarm and interlock protection, high water level alarm, steam pressure ultra-high alarm and interlock protection and other automatic control functions;

- Mechatronics, take up little space, the whole fast installation factory, easy to install and use;

- The steam boiler starts up regularly and shuts down regularly. There is no need to be a full-time stoker. Generally speaking, it is very simple to start the boiler by pressing the “start” button and stop the boiler by pressing the “stop” button.

Steam Boiler Working Process

The workflow of a steam boiler should be as follows. Each procedure requires care and patience. The raw water goes through the feed pump into the pipeline of the separator and the evaporator (the two are connected). The liquid level is controlled by the connection of the liquid level sensor and PLC, and the industrial steam enters into the shell side of the evaporator to heat the raw water in the pipe side to the evaporation temperature, and the raw water is transformed into steam. The steam in the low speed and the height of the separator of the small droplets by gravity separation out back to the raw water, to evaporation, the steam is turned into a pure steam through a specially designed to clean after enters the separator at the top of the screen device, through the pipe the output of pure steam into the various allocation and use of point in the system.

Wuxi Zozen Boilers Co.,Ltd, as one of the professional boilers manufacturers in China. The pays great attention on technological innovation and product development, setting up technology research and development center and laboratory, the advanced set of boilers testing equipment. The boilers in Zozen Company are sold remotely to UK, Canada, India, Philippine, etc. Any need? Just Contact Us Zozen!