Product Thermal Capacity: 0.35-14 MW

Working Pressure: 0.7-1.25 Mpa

Available Fuel: Nature gas, coke oven gas, biogas, methanol, liquid propane gas, diesel, heavy oil, light oil, crude oil, etc.

Available Industries: Heat supplying, hospital, hotel

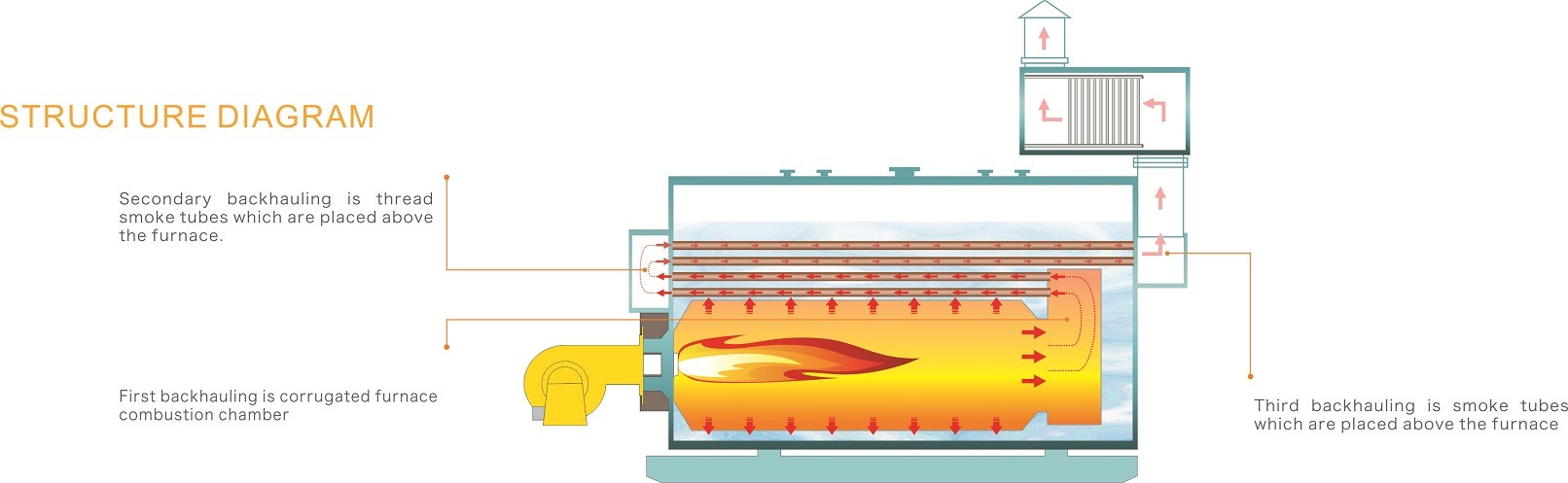

Product Introduction:WNS series hot water boiler is a quick installation horizontal internal combustion three-return fire tube structure. The bifurcated furnace pipe is arranged with wet back, and the high-temperature flue gas is washed into the second and third return flue pipes successively, and then discharged into the atmosphere through the chimney through the back flue chamber.

WNS Series Hot Water Boiler Introduction

WNS series oil/gas fired hot water boiler is a quick installation horizontal internal combustion three-return fire tube structure. The bifurcated furnace pipe is arranged with wet back, and the high-temperature flue gas is washed into the second and third return flue pipes successively, and then discharged into the atmosphere through the chimney through the back flue chamber. The boiler is equipped with high quality burners, and adopts advanced technologies such as automatic proportional regulation of combustion, automatic regulation of water supply, program start and stop, automatic operation, etc., and has automatic protection functions such as temperature control of running water, over-temperature, over-pressure extinguishing. This type of boiler has the characteristics of compact structure, safe and reliable, simple operation, quick installation, less pollution, low noise, high efficiency, widely used in enterprises, hotels, hospitals, office buildings, civil buildings and other facilities for industrial steam and life as well as heating.

Oil/Gas Hot Water Boiler Advantages

- WNS series hot water boiler adopts three-return horizontal wet-back structure with edge butt-welding, which improves the reliability of boiler.

- Combustion chamber low position layout design. Increased safe water level range in boiler. The possibility that an accident will occur due to lack of water. The lowest is the lowest.

- Combustion chamber adopts large volume design. Fuel is burned more fully, improving combustion efficiency.

- The smoke pipe of hot water boiler is connected with tube plate. “Expansion, welding, expansion” process. By eliminating the gap between pipe and pipe hole and welding residual stress, the thermal and fatigue cracks of pipe plate and high-temperature smoke pipe mouth are effectively avoided.

- The threaded pipe with high heat transfer coefficient is adopted to enhance the convective heat transfer effect. Reduce the exhaust temperature and improve the thermal efficiency of boiler.

- The combustion chamber of hot water boiler adopts full ripple furnace structure, good flexibility, strong resistance to external pressure: turbulence is strong. Good perturbation. Enhanced heat transfer, high thermal efficiency. It also increases the area under heat.

- Design of rear view device for hot water boiler. Easy to observe combustion conditions.

- The thermal insulation layer of hot water boiler is made of high thermal resistance material with good thermal insulation effect. Color board outer packing, beautiful and generous appearance.

- The front and rear panels of the hot water boiler adopt hinged opening structure, which is convenient for maintenance and repair.

- Choose high quality burner, advanced technology. Reliable operation; It has a furnace purge. Automatic ignition. Ignition detection, gas high pressure protection. Low pressure gas protection, leak detection and other functions. Ensure safe operation.

- This series of hot water boiler is equipped with computer intelligent controller, voice human-machine interface, touch button, easy to operate.

Security Protection Configuration

It has high and low water level, overtemperature and overpressure. Interlock protection functions, such as fault self-check protection, burning machine failure flameout, alarm, etc. It has the functions of large and small fire automatic control and combustion working time record, temperature control free setting, multi-period working time free setting, clock, calendar, fault point automatic indication and automatic water supply function. It has the functions of display, alarm and record of the temperature of medium and smoke exhaust.

Control System States That

The oil fired hot water boiler developed by our factory adopts the international advanced automatic burner as the main combustion equipment. The burner combustion process is controlled by a more advanced burning program controller, can realize the normal fuel boiler combustion required for a variety of functions, can be in normal state, the accident state, in an extraordinary situation, implement protective boiler stop automatically, with pressure proportional controller, temperature controller, high and low temperature indicator, overpressure, adjusting, ensure water level fluctuations within the normal range.

WNS Series Hot Water Boiler Control Principle

After the power switch is closed, the pump control switch is transferred from the stop position to the manual position for boiler feed water. After rising to the normal position, turn the pneumatic and automatic manual switches to the automatic position, then close the burner power switch, turn the fire switch of the controller to the firing position, and finally press the start button. The power of the control system is switched on, the burner enters the working state, according to the action program of the program controller, start the blower into pre-purging, then adjust the damper to spray oil from the position of small fire, ignite the small fire and then enter the state of big fire, and enter the normal operation stage of the boiler.

Oil/Gas Hot Water Boiler Product Parameter

| Model | WNS1-0.7-Y(Q) WNS1-1.0-Y(Q) |

WNS1.5-1.0-Y(Q) WNS1.5-1.25-Y(Q) |

WNS2-1.0-Y(Q) WNS2-1.25-Y(Q) |

WNS3-1.0-Y(Q) WNS3-1.25-Y(Q) |

WNS4-1.25-Y(Q) WNS4-1.6-Y(Q) |

WNS5-1.25-Y(Q) WNS5-1.6-Y(Q) |

|

| Rated steam capacity (t/h) | 1 | 1.5 | 2 | 3 | 4 | 5 | |

| Rated working pressure(Mpa) | 0.7/1.0 | 1.0/1.25 | 1.0/1.25 | 1.0/1.25 | 1.25/1.6 | 1.25/1.6 | |

| Rated Steam temperature(°C) | 170/184 | 184/194 | 184/194 | 184/194 | 194/204 | 194/204 | |

| Feed water temperature(°C) | 20 | 20 | 20 | 20 | 20 | 20 | |

| Heating area(m²) | proper | 24.06 | 27.33 | 58.15 | 89.99 | 112.59 | 163.1 |

| Condenser | 15.4 | 20.5 | 29.64 | 45.6 | 53.54 | 65.89 | |

| Thermal efficiency(%) | >98 | >98 | >98 | >98 | >98 | >98 | |

| Fuel available | Natural gas,biogas,coke gas,methanol,light oil etc. | ||||||

| Combustion equipment | burner | ||||||

| Total power(KW) | 3.6 | 4 .8 | 7.0 | 10.5 | 13 | 16.5 | |

| Feed pump model | JGGC2-8×16 | JGGC2-8×16 | JGGC2.4-8×18 | JGGC4-8×18 | JGGC4.8-8×22 | JGGC6-8×18 | |

| Fuel consumption | Natural gas | 72 | 108 | 144 | 216 | 288 | 360 |

| Light oil | 66 | 99 | 113 | 196 | 266 | 332 | |

| Weight of biggest part for transportation(t) | 4 | 4.5 | 8.5 | 8.9 | 13.3 | 14.3 | |

| Overall dimension of boiler assembled(m)(L×W×H) | 3.25×1.8×2.1 | 3.0×1.8×2.01 | 4.4×2.1×2.46 | 4.6×2.31×2.62 | 4.7×2.48×2.85 | 5.33×2.65×3.3 | |

Oil/Gas Fired Hot Water Boiler Control Function

- Boiler temperature control;

- Boiler outlet water temperature control;

- Anti-freezing control;

- Water shortage and overtemperature protection;

- Self-test for sensor failure;

- Fuel shortage indication;

- Alarm when burner flameout;

- Hot water pump control.