Boiler Capacity:700-14000 KW

Working Pressure: 0.8-1.0 MPA

Available Fuel: Natural gas, coke oven gas, bio-gas,liquefied petroleum gas, diesel, heavy oil, light oil, crude oil etc.

Application Scale: Petroleum, chemical, chemical fiber, pharmaceutical, textile printing and dyeing, building materials, wood processing, vegetable oil processing and other industries

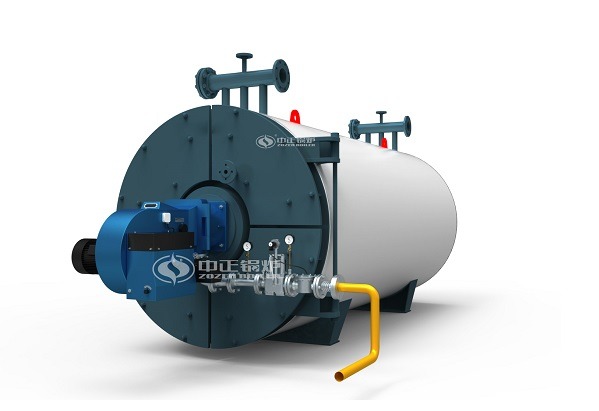

Product Introduction:YQ(Y)W series thermal oil boiler is a new type of heating equipment which uses oil or gas as fuel and heat conduction oil as conduction medium. It has the advantages of full fuel combustion, high combustion efficiency, convenient operation and maintenance, high heat utilization rate etc.

YQ(Y)W Series Thermal Oil Boiler Description

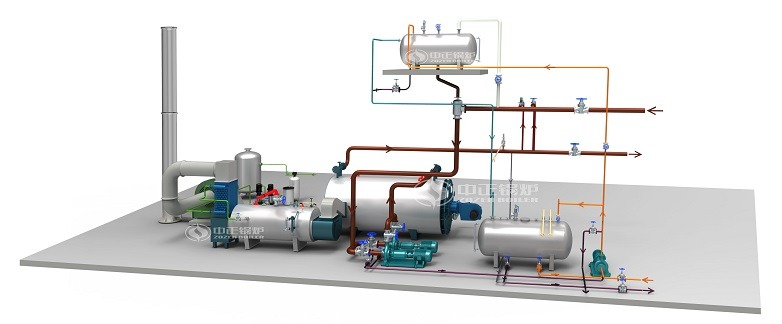

Thermal oil boiler is also called (organic heat carrier boiler), oil (gas) as the fuel, heat conduction oil as medium, using hot oil circulation pump forced medium liquid loop, to transfer heat to heat equipment returned again after reheating, heating furnace under low pressure for high working temperature, and can run for medium to high precision control work. The system has high heat utilization rate. Because the module is installed as a whole, it is convenient to operate and maintain. It is an ideal heating equipment with safety, high efficiency and energy saving. Fuel oil (gas) by the burner after the ignition of the high temperature flame into the inner coil tube to form a radiation heating surface, through the back of the inner coil to rotate 180° forward into the inner and outer tube sandwich area to form a convection heating surface. Then the upper part of the interlayer enters the second interlayer area of the middle and outer coils, and the air is discharged into the chimney at the back of the second interlayer area.

Gas/Oil Thermal Oil Boiler Structural Characterisation

1. Flue gas flow:

The boiler adopts horizontal structure, combustion mode for chamber combustion, fuel for natural gas, city gas, liquefied gas. The flue gas flow is: the fuel is burned in the furnace, and the high temperature flue gas is absorbed by the inner coil tube. The inner ring coil outlet flows into the channel between the inner ring and the outer ring to form a return trip. Through the passage between the outer ring and the external insulation flows, forming a second return flue gas through the exit smoke box into the rear flue, through the heat exchanger into the chimney, through the chimney into the atmosphere.

2. Structural characteristics and specifications:

- The heating surface of the furnace body adopts inner and outer coil tubes, the tube ring is about 30 laps, the pipe size is φ57×3, the inner and outer rings are connected in series; The heat carrier enters the inner coil from the outer coil and then flows into the service system.

- The inner and outer coil tubes are PN16, DN50 specifications, made of Φ57 ×3 pipes, and made of 20(GB/T3087-2008).

- The interface of thermometer and pressure gauge adopts DN15 interface, and the nozzle adopts φ22×4.

- The main boiler is packaged by the main body, the inner body is the boiler body, and the outer body is the insulation layer.

YQ(Y)W Series Thermal Oil Boiler Advantage

- The boiler adopts an advanced control system to control the medium, with high thermal efficiency and convenient maintenance.

- The oil/gas fired thermal oil boiler has a compact structure and saves floor space.

- YQ(Y)W series boilers integrate automatic detection, control, and interlocking alarm prompts. The boiler operation does not need to be on duty, saving manpower.

- The size of the furnace is matched with the burning flame, and the radiation heat transfer rate is high.

- The heating system is simple, no water treatment equipment is needed, and investment is reduced.

- The coil structure is adopted, the heating surface is sufficient, and the thermal efficiency is high.

- It is easy to install, as long as the main body and the combustion chamber are closed.

- An air preheater is installed at the end of the boiler, which greatly improves the efficiency of the boiler.

- The heating can be as high as 300℃ and the general working pressure is below 1MPa, making the boiler operation safe and reliable.

- The diameter and length of the radiant coil are compatible with the flame of the matched burner, which ensures the reliable operation and sufficient cooling of the coil.

Determination of Pipe Velocity

The recommended flow rate in Organic Heat Carrier Furnace:

Radiation segment, V1 > 2m/s; Convection section, V2 > 1.5 m/s

Calculation results: V1= 3.99m/s in the inner coil and V2=3.99m/s in the outer coil.

The maximum allowable liquid film temperature of the organic heat carrier used is TFPermit =370℃. The highest liquid film temperature TFILM =329.51℃ was calculated for oil-fired boiler and 328.68℃ for gas-fired boiler.

YQ(Y)W Series Thermal Oil Boiler Product Parameter

| Model | Rated thermal power (KW) | Rated thermal power (x104kcal/h) | Design working temperature(≤℃) | Rated working pressure(MPa) | Thermal efficiency (≥%) | System installation power(KW) | Maximum transport size(m) (L×W×H) |

| YQW-1400 Y(Q) | 1400 | 120 | 320 | 0.8 | 95 | 35 | 4.3×2.0×2.6 |

| YQW-1800 Y(Q) | 1800 | 160 | 320 | 0.8 | 95 | 56 | 4.9×2.2×2.6 |

| YQW-2400 Y(Q) | 2400 | 200 | 320 | 0.8 | 95 | 56 | 5.3×2.5×3.0 |

| YQW-2800 Y(Q) | 2800 | 240 | 320 | 0.8 | 95 | 66 | 6.1×2.5×3.0 |

| YQW-3500 Y(Q) | 3500 | 300 | 320 | 0.8 | 95 | 75 | 6.7×2.6×3.0 |

| YQW-4200Q | 4200 | 360 | 320 | 0.8 | 95 | 95 | 6.9×2.7×3.2 |

| YQW-4600Q | 4600 | 400 | 320 | 0.8 | 95 | 95 | 7.0×2.9×3.4 |

| YQW-6000Q | 6000 | 500 | 320 | 0.8 | 95 | 140 | 7.2×3.3×3.9 |

| YQW-7000Q | 7000 | 600 | 320 | 0.8 | 95 | 140 | 8.0×3.6×4.0 |

| YQW-8200Q | 8200 | 700 | 320 | 0.8 | 95 | 140 | 8.5×3.7×4.0 |

| YQW-9400Q | 9400 | 800 | 320 | 1 | 95 | 200 | 9.5×3.8×4.0 |

| YQW-10500Q | 10500 | 900 | 320 | 1 | 95 | 200 | 10.5×3.8×4.0 |

| YQW-12000Q | 12000 | 1000 | 320 | 1 | 95 | 240 | 12.4×3.8×4.0 |

| YQW-14000Q | 14000 | 1200 | 320 | 1 | 95 | 300 | 13.5.×4.0×4.2 |