Boiler Capacity:1-20t/h

Working Pressure: ≤3.82MPa

Available Fuel: Nature gas, coke oven gas, blast furnace gas, carbon black off-gas, biogas, LPG, diesel, heavy oil, light oil, crude oil, etc.

Available Industries: Heat supplying, chemical, food, textile, printing and dyeing, cigarettes and tobacco, fodder, pharmacy, building materials, brewery, rubber, hospital etc.

Boiler Introduction: Horizontal quick installation internal combustion three return fire tube boiler. The high temperature flue gas is washed into the process flue pipe and then discharged into the atmosphere through the chimney from the back flue chamber. The boiler is equipped with movable front and rear smoke box covers to facilitate boiler maintenance.

Condensing Steam Boiler Introduction

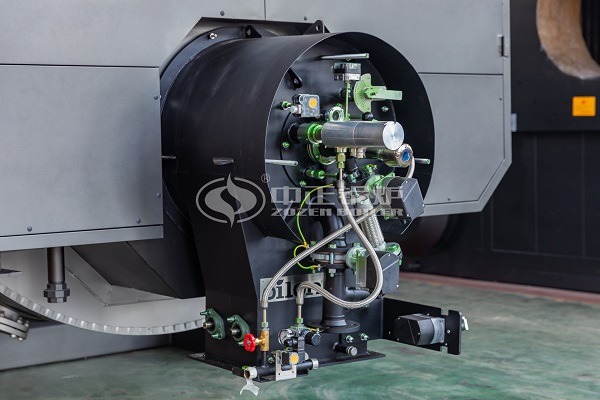

The condensing oil/gas steam boiler is a horizontal quick installation internal combustion three return fire tube boiler. The high temperature flue gas is washed into the flue pipe in turn, and then discharged into the atmosphere through the chimney from the rear flue chamber. The boiler is equipped with movable front and rear smoke box covers to facilitate boiler maintenance. The boiler is equipped with a burner with good technical performance, which adopts advanced technologies such as automatic proportional adjustment of combustion, automatic adjustment of water supply, program start and stop, automatic operation, and has automatic protection functions such as high and low water level alarm and extremely low water level, ultra-high steam pressure and flameout. This type of boiler has the characteristics of compact structure, safe and reliable, easy operation, quick installation, less pollution, low noise, high efficiency. The condensing oil gas steam boiler is a boiler product developed in cooperation with Germany, and its technical indexes have reached the industry level. This kind of boiler truly achieves clean combustion, pollution-free emission, convenient operation and sufficient output.

Condensing Oil/Gas Boiler Advantages

- On the basis of analyzing and summarizing the research results of the relationship between the condensation efficiency and the exhaust temperature, the relationship between the condensation efficiency and the thermal efficiency, and the corrosion rate of the condensate on different steels, through the reasonable design of the heating surface, the exhaust temperature is greatly reduced to ensure that the vapor in the flue gas can meet the design requirements of the condensation rate. It is a kind of condensing boiler which can absorb the sensible heat of flue gas and the latent heat of vaporization released in the process of condensation of water steam, thus greatly improving the thermal efficiency of the boiler.

- Based on the low heating value of the fuel, the thermal efficiency is over 100. Boiler thermal efficiency is high; Adopt automatic burner, water supply adopts continuous electric regulation, high combustion efficiency. Safe and stable: design over temperature, over pressure, water shortage, leak detection, flameout and other protection functions, boiler operation is safe and reliable.

- Condensing oil/gas boiler furnace body structure is horizontal wet-back three return fire tube type, waveform furnace, under the furnace chamber, the front and rear smoke box, the base is saddle type, the appearance of milky white color plate with soft color. Symmetrically arranged heat transfer pipe, threaded pipe and light pipe combined, the large heat transfer area makes the boiler thermal efficiency of more than 98%.

- Production process to eliminate imported boiler fillet weld safety hazards, extremely harsh use of butt welding, increase the boiler safety factor, delay the service life of the boiler. The boiler is the upper feed water, because the water is always in high speed turbulence, so that the convection, radiation, conduction maintain in the ideal state, and constantly destroy the bubble and other fixtures at the laminar flow boundary. So as to ensure that the heating surface of the boiler has good water cooling.

- The low-position combustion chamber makes the safe range of water level larger and the gas phase space of the boiler larger. The unique steam separator ensures the quality of steam (steam dryness reaches more than 97%).

Condensing Oil/Gas Steam Boiler Description

The water level control system of this series steam boiler adopts electrode type water level control, setting high, medium and low extremely low water level protection. The control has a multi-layer safety interlock protection device, such as: steam pressure protection, high temperature protection, burner flameout protection, safety valve protection, password protection, explosion-proof door protection, so that the safe operation of the boiler is always under control. The boiler is manufactured for the whole machine, the primary valve instrument with reliable performance is selected, the burner and the feed water pump are imported brands, to ensure that every link of the boiler is reliable. In accordance with the design specifications, the furnace inspection door, head hole, hand hole, fire observation hole, explosion-proof door and front and rear open cigarette box door are provided for easy maintenance and cleaning.

Condensing Steam Boiler Application

Condensing steam boiler is widely used in hospitals, schools, textile mills, garment factories, large supermarket, garment factories, dyeing factory, hotel, dining room, restaurant, food factory, beverage factory, soy products, meat products factory, cannery, brewery, pharmaceutical factory, packaging plant, building materials factory, paint factory, swimming pool and other places of the enterprises and institutions.