Installation Method: quick installation, assembly

Circulation Method: assisted, natural

Combustion Method: chamber burner

Fuel Classification: various biomass fuels

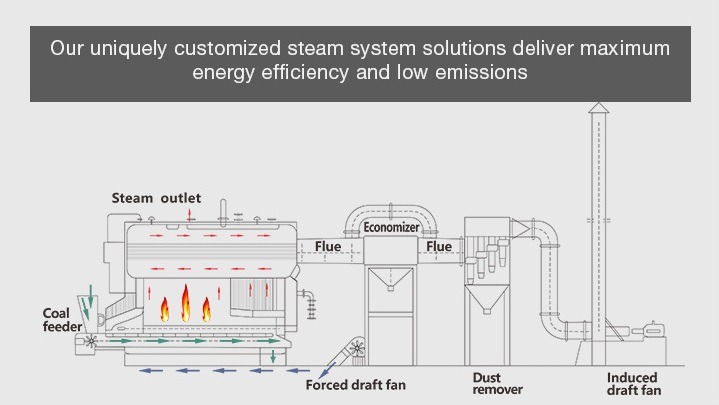

Product Introduction: Biomass steam boiler is mainly composed of main body, chain grate, frame outer skin, platform escalator, piping system, energy saver, flue duct, dust collector, blower, induced draft fan, electric control cabinet, etc.

Biomass Fuel Introduction

Biomass pellet fuel is the use of straw, rice stalks, fuelwood, wood chips, peanut shells, melon seed shells, corn cobs, sugar beet meal, bark and other waste crops, through crushing-mixing-extrusion-drying processes. Make pellet fuel. Its raw materials are widely distributed and the processing technology is advanced. Biomass particles are known as green coal and are a kind of clean energy. As a boiler fuel, it has a long burning time, a high temperature in the enhanced combustion furnace, and is economical and does not pollute the environment. It is a renewable energy source. The burned ash is a very good fertilizer that can be recycled. It can replace traditional boilers to burn wood, coal, natural gas and other resources. It is an environmentally-friendly product with high efficiency and energy saving.

Product Description of Biomass Steam Boiler

- Enhanced heat transfer: This steam boiler adopts threaded smoke tube, the heat transfer coefficient of threaded smoke tube is as much as twice that of bare tube, and the optimized design is carried out while ensuring a high heat transfer coefficient to ensure proper flow resistance, No dust accumulation, low wear, high strength and fatigue resistance.

- The self-cleaning ability of the threaded smoke pipe of DZL type boiler is strong, and the flow rate of the flue gas of the threaded smoke pipe can still be above 8m/s at half load, and the self-cleaning ability of the threaded smoke pipe (high speed of rotation) The airflow will take away the ash collection below half load). This phenomenon of no ash collection makes the output and efficiency of this type of boiler remain unchanged during the year-round operation.

- The boiler is a kind of low nitrogen oxide biomass boiler with variable arch structure, including front, middle and back three sections of air chambers, chain or reciprocating grate, and a combined arch composed of a front supply and a rear supply. The front section and rear section of the air chamber are arranged at the bottom of the bottom of the boiler to realize the segmented air distribution. The grate is arranged above the front section and the rear section of the air chamber. The fuel and combustion characteristics of biomass enable the boiler to adapt to a wide variety of biomass, with good burnout and low pollution emissions.

Features of Biomass Fired Water Tube Steam Boiler

- It adopts a single drum is arranged longitudinally, compact structure, small footprint, and good flame fullness.

- The furnace is in the form of a curved water-cooled wall tube, a drum, and left and right headers, which can expand upwards freely.

- The water wall adopts light pipe water wall, which is easy to manufacture and process.

- The convection tube in the boiler barrel adopts threaded smoke tube to improve the winding of working medium and increase heat transfer.

- The outer packaging guard plate adopts a pressed guard plate, which has a beautiful appearance.

- High thermal resistance material is used as the thermal insulation layer, which has good thermal insulation performance.

- The unique double-layer secondary air design improves the ignition conditions of biomass fuels. The independent air chamber is adopted to achieve reasonable air distribution, so that an aerodynamic field conducive to combustion is formed in the furnace, making the combustion temperature high and burning efficient.

Biomass Water Tube Boiler Sales Service

Pre-sale

- Selection of equipment model;

- According to the parameter requirements provided by the user and the boiler installation location, select the corresponding appropriate product;

- Provide technical consulting services to customers;

- The company sends engineering and technical personnel to the site to plan the site for users and design the preliminary boiler room floor plan.

On sale

- Arrangement of production tasks, matching and inspection of various materials;

- Product manufacturing, process flow, in-plant inspection and acceptance by the Special Inspection Institute;

- Design the construction plan, determine the layout of the boiler room, and confirm the basic size of the equipment;

- Equipment installation, commissioning, and acceptance;

- On-site training of operators.

After sale

- 24-hour no-rest after-sales response, 24-hour no-rest troubleshooting;

- Regular return visits and free technical guidance.

Customers in Use