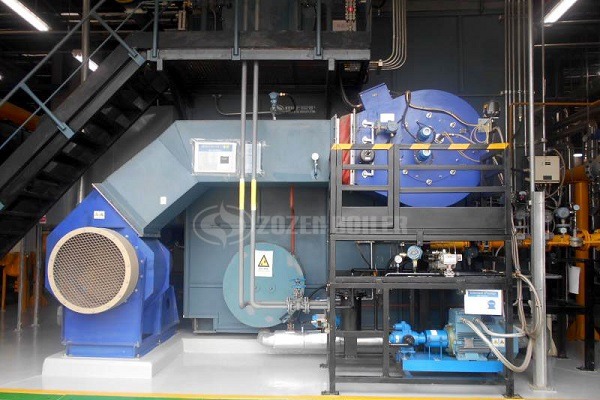

Case name: 30 tph and 40 tph SZS gas-fired watertube boiler project for Samsung Electronics

Case type: Gas-fired boilers cases

Equipment: 3 sets of SZS30-1.25-Q, 2 sets of SZS40-1.25-Q

Capacity: 30 tph, 40 tph

Location: Xian, Shanxi

Project boiler medium: Steam

Company name: Samsung Electronics

Customer Feedback:

We have very strict standards for partners. In 2012, the steam boilers provided by ZOZEN are really high-efficiency and energy-saving. Water tube boiler fully automatic safe operation design helps us save the running costs. We are really satisfied with their excellent construction ability and perfect support service. Therefore, we are pleased to cooperate with ZOZEN again for our second semiconductor line.

Case Introduction:

Samsung Electronics is the largest electronics company in South Korea. In 2012, Samsung Electronics had invested $7 billion to build the first semiconductor line in Xi’an, China. The water tube boiler plays an important role in the semiconductor production workshop, making it keep a constant temperature, humidity and an ultra-clean environment. Samsung Electronics compared with many international boiler manufacturers. ZOZEN held the chance with our powerful comprehensive strength. Based on its actual demand, ZOZEN helped them make a tailor-made solution, providing 2 sets of 40 tph and 3 sets of 30 tph SZS series gas-fired steam boilers. The construction of its second semiconductor line starts in 2018. ZOZEN is still chosen to cooperate with Samsung Electronics, providing 5 sets of 30 tph SZS series gas-fired steam boilers. This kind of boiler is a typical high efficiency and low consumption boiler, which features a D-type chamber combustion structure. The furnace is designed to be large and the heating area is arranged sufficiently, which will make sure that the fuel is fully burned. Adding the spiral finned tube condensator at the end of flue gas duct makes the thermal efficiency reach above 98%.

SZS series boiler natural circulation, drum longitudinal arrangement, full membrane type water wall structure, micro positive pressure combustion. The furnace of this series water tube boiler is covered by membrane wall, and the flue gas enters the convection tube bundle connected between the upper and lower boiler tubes from the outlet of the furnace. This steam boilers after the flue gas flows through the convection tube bundle, it enters the heating surface of the tail – ND steel spiral fin economizer and condenser, and finally enters the chimney into the atmosphere through the flue.